Installation Video

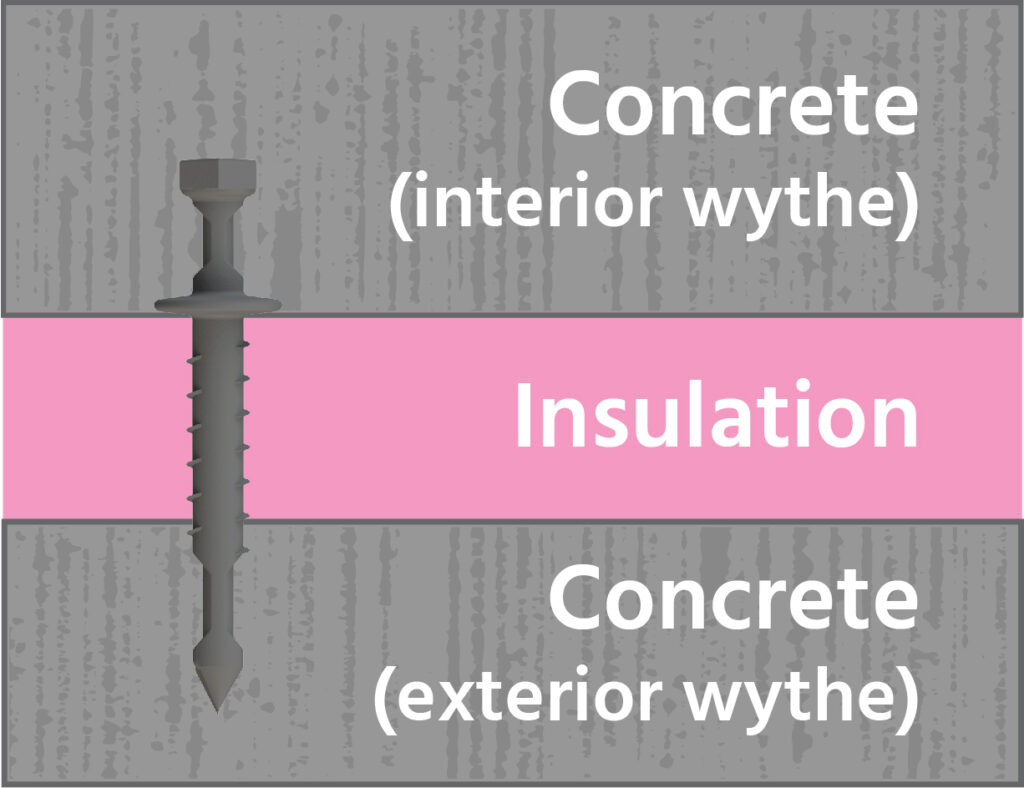

The animation video below shows how the HK Standard (ST) ties are used in a typical tilt-up concrete sandwich panel.

Application

HK Standard (ST) ties are designed for use in tilt-up and precast panels. These ties may be used in most tilt-up and precast applications where:

- The fascia is 2–4 inches (50–100 mm) thick

- If fascia is suspended, the rigid insulation has a density of at least 1.3 lb/ft³ (20.82 kg/m³) and fascia is not more than 3 inches (75 mm) thick

- The panels will not extend beyond 60 ft (18.2 m) above grade unless the fascia is unsupported or the temperature difference between the inside and outside wythes will not exceed 55°F (13°C)

- The concrete compressive strength at the time of lifting is at least 2,500 psi (17.2Mpa)

For your convenience, you can download these instructions as a printable PDF.

These instructions replace the previous document titled “Installation Instructions Pub. No. HK-ST-II”

Detailed Installation Instructions

After form work is completed and casting beds are prepped, proceed with the following steps to install the HK Standard (ST) ties:

- Prepare and place exterior wythe concrete

- Install rigid insulation

- Install connector ties

- Adjustments around openings / at panel edges

- Check tie consolidation

- Fill gaps and holes in insulation

- Prepare interior wythe

- Perform on-site quality assurance testing

- Place interior wythe

- Panel completion

Rain Warning

Concrete cure time varies depending on environmental conditions and additives. DO NOT use this system while it is raining or if rain is imminent when panels will be exposed to rainfall during installation of ties until concrete has cured sufficiently to not be adversely affected by rainfall. If your panel casting area is unprotected from the elements, it is necessary to protect the concrete should it rain during installation of ties. Water in the casting bed will cause the insulation to float and it will lower concrete strength, which will either cause ties to pull out of the plastic concrete or it will weaken the concrete anchorage.

Disclaimer of Liability

It is the sole responsibility of the contractor to install the HK ties in accordance with the published instructions. It is also the responsibility of the owner to confirm proper industry standards and methods are used by contractors, engineers, suppliers, and all others hired by the owner. The presence of an HK Composites representative at the job site does not relieve the contractor from the responsibility to follow published installation instructions. HK COMPOSITES IS NOT RESPONSIBLE FOR ANY LIABILITY RESULTING FROM A FAILURE TO FOLLOW THESE INSTRUCTIONS. Our recommendations should not be taken as a construction specification nor inducements to infringe on any patent or violate any law, safety code or insurance regulation.

1. Prepare and place exterior wythe concrete

Clean debris from casting surface. Apply release agent as specified by the release agent manufacturer. Place reinforcing steel or welded wire fabric sheets on proper reinforcement supports. Use care to minimize disturbing the release agent—even simple liquids such as a spill from soft drinks can break the bond breaker seal. Clean debris once again before placing concrete.

- Concrete strength – The 28-day compressive strength should be at least 4,000 psi.

- Low slump – The concrete slump specified must be maintained during installation of the insulation system. If used in a high-temperature environment, a low slump concrete becomes problematic. Under these conditions a lower slump concrete will reach initial set quite rapidly and the concrete could set before the ties can be vibrated. Please refer to “ACI 305 – Specification for Hot Concreting” and “ACI 306 – Specification for Cold Weather Concreting”.

If a low slump concrete is used, the concrete tends to form air pockets as the ties are pushed through the insulation. It is extremely difficult to force low slump concrete to flow back around the anchor tip of the connector tie. Even if the ties are mechanically vibrated after installation, there is a possibility that anchorage will not be achieved for all the ties.

Place concrete in forms. The fascia wythe concrete should be thick enough to provide sufficient cover for the reinforcement and allow adequate embedment for the ties. A minimum thickness of 2 inches for fascia wythes is required. Textures, recesses, and reveals depths are in addition to this minimum thickness.

HK Standard (ST) ties are designed to keep a 2–4 inch (50–100 mm) fascia layer of concrete affixed to the panel. If outside of that range, please contact the HK engineering team to review design criteria.

Vibrate concrete as necessary to create proper consolidation of concrete around the tie. For proper vibration equipment and techniques refer to “ACI 309 – Guide for Consolidation of Concrete”. Use care to not disturb bond breaker with stick vibrators.

Strike off with a screed and level concrete to the specified thickness.

2. Install rigid insulation

HK Composites carries a full line of rigid insulation to meet any specifications. One common service offered is off-site pre-fabrication of the rigid insulation, which may include preformed holes and precut insulation that conforms to engineered shop drawings.

Before installing the insulation, each sheet of rigid insulation should already have preformed holes or should be marked on 16 to 17-inch centers (400–435 mm) to indicate where ties should be inserted through the rigid insulation.

Place rigid insulation board on poured concrete immediately after screeding (within approximately 15–30 minutes).

Work in a methodical manner to place rigid insulation sheets, edge to edge, from one end of the panel to the other. Use care to ensure each insulation sheet is positioned according to the approved details for the project.

After the first insulation sheet is in place, it may be helpful to set each subsequent sheet on the face of the previous sheet then slide it into place, allowing it to drop into position adjacent to the previous sheet.

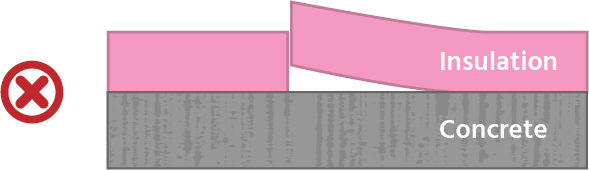

The insulation sheet face must be entirely flat against the concrete. If the insulation board has a camber or bow, it needs to be weighted down to a flat position. Concrete still needs to be in plastic state.

Minimize gaps or spacing between each rigid insulation sheet and between the edges of the panel and the forms.

Visual inspection

All rigid insulation boards must be inspected to ensure the face is flat and in full contact with the face wythe of concrete.

If rigid insulation has a bow or bend during the installation process, it can be weighted down to rest face-down in full contact with the concrete.

If a bow or bend is exhibited after the ties have been installed, please follow Step 4 instructions to install additional ties.

3. Install connector ties

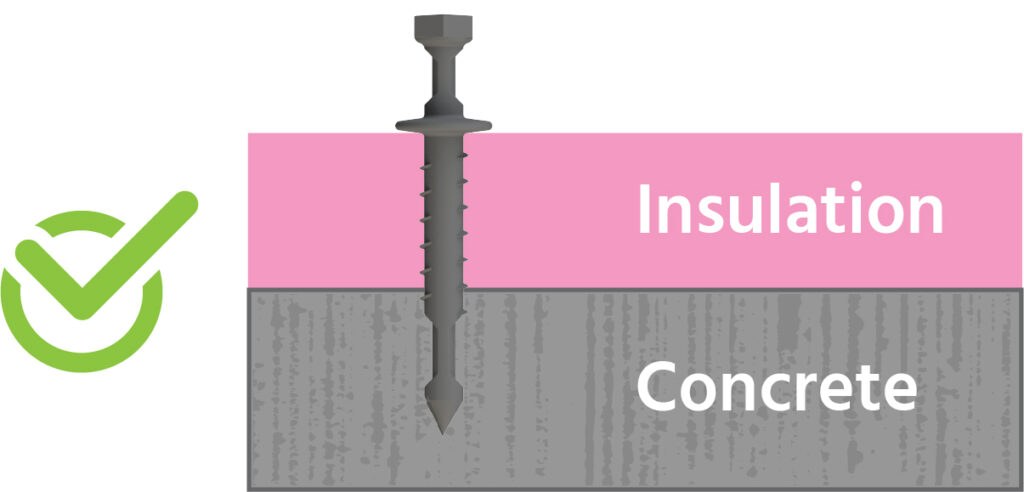

The HK Standard (ST) ties should be installed immediately after placing the rigid insulation sheet on the wet concrete. Push the pointed end of the tie through the preformed holes or marked dots on the rigid insulation into the fresh concrete until the embedment collar is seated firmly against the top surface of the rigid insulation.

Optionally, ties may be pre-installed through the rigid insulation or pushed partially through the rigid insulation before placing the insulation sheets on the concrete.

To promote concrete consolidation around the tie, apply repetitive foot pressure on the insulation sheet near each tie or otherwise vibrate the tie or the area around the tie. For insulation thicknesses of 3 inches (75 mm) or greater, mechanically vibrate each connector using a concrete vibrating screed (idle setting) or an air actuated vibrator.

Visual Inspection

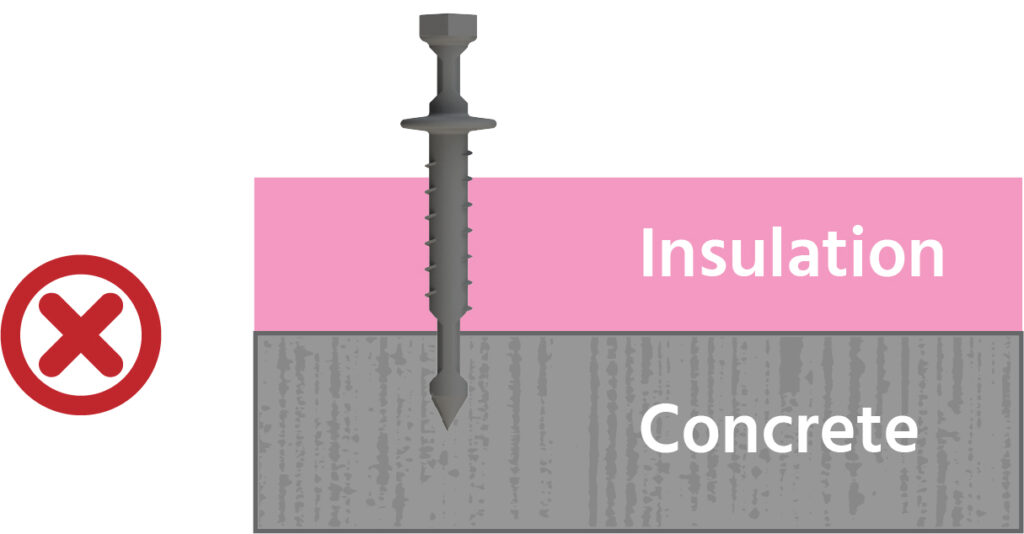

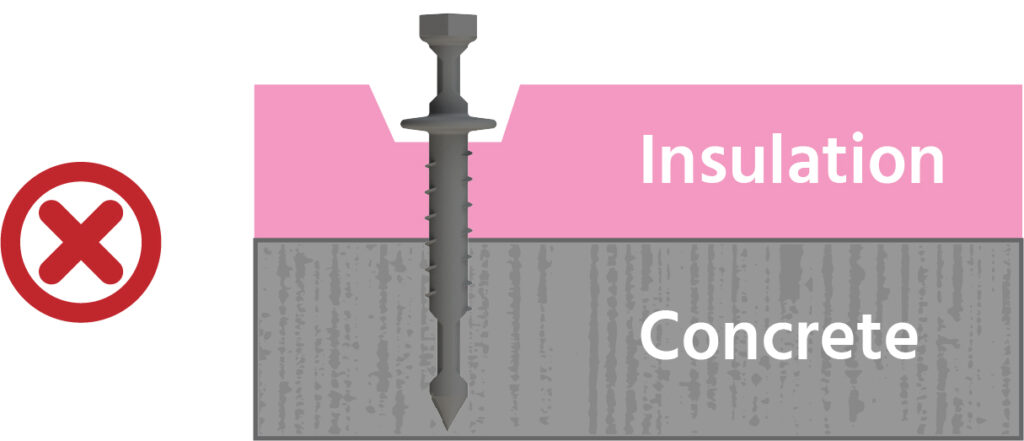

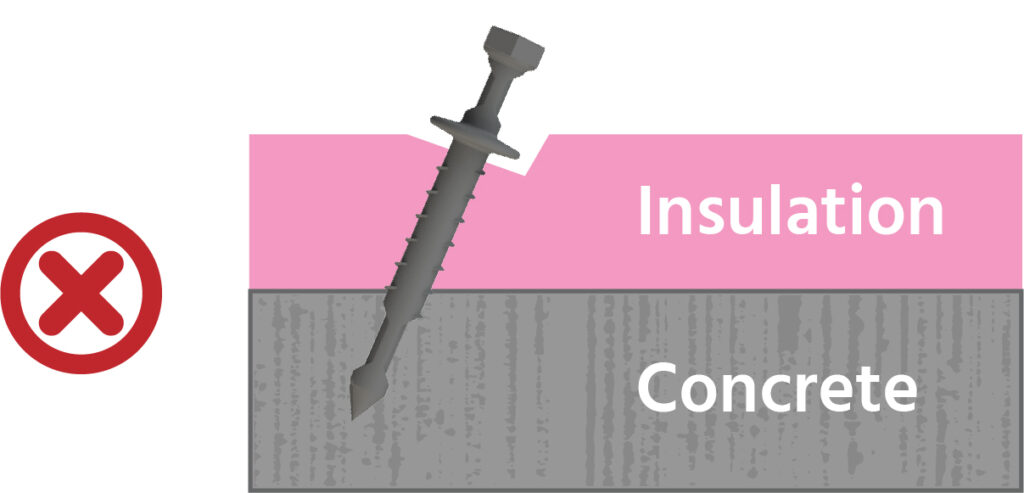

Each installed HK Standard (ST) tie should be visually examined for proper embedment and consolidation in the concrete face.

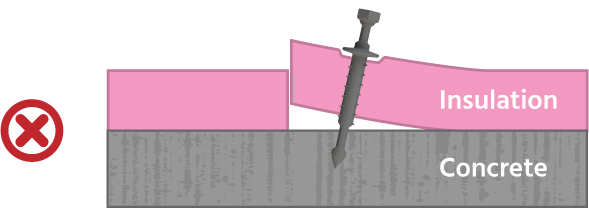

If any of the tie installation conditions displayed below occur, please follow the Alternate Tie Installation Instructions.

Raised tie – If a tie collar is 1/4 inch proud or greater from the insulation, follow the Alternate Tie Installation Instructions to install an additional tie nearby.

Depressed tie – If a tie collar is depressed into the insulation 1/4 inch or greater, follow the Alternate Tie Installation Instructions to install an additional tie nearby.

Skewed tie – If a tie is skewed from the insulation greater than 15°, follow the Alternate Tie Installation Instructions to install an additional tie nearby.

4. Adjustments around openings / at panel edges

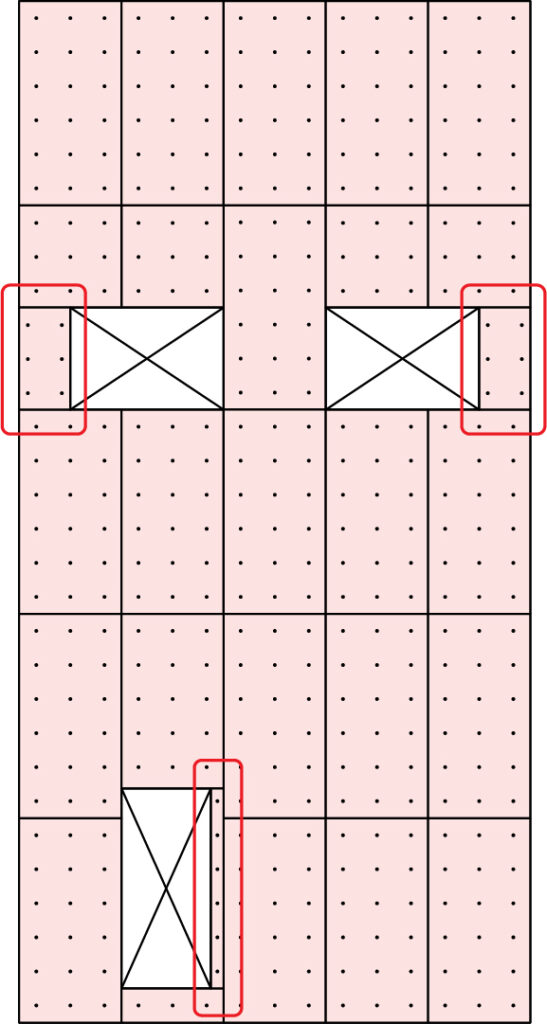

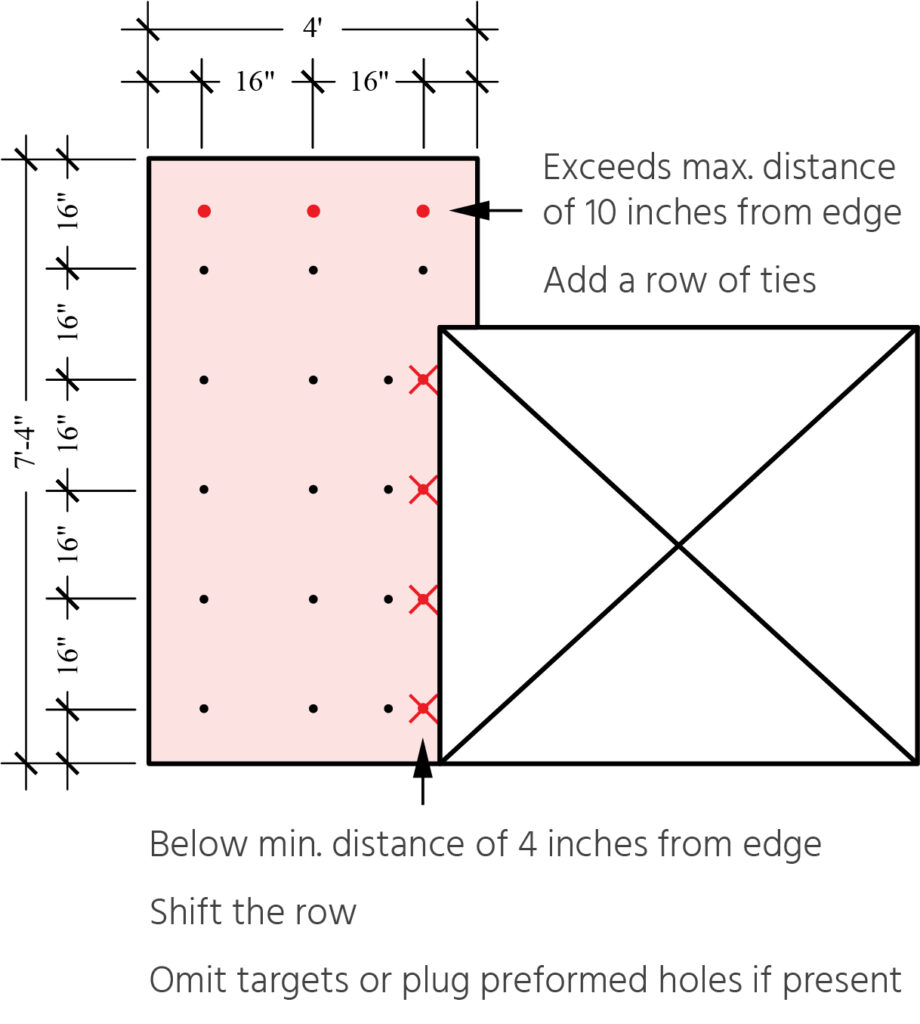

HK Standard (ST) ties should be installed no closer than 4 inches (100 mm) and no further than 10 inches (250 mm) from openings or the panel edges.

If the tie installation is less than 4 inches (100 mm) from a panel edge or opening, shift the tie to fall within the required realm as displayed in Figure 2.

If the tie installation is greater than 10 inches (250 mm) from a panel edge or opening, add extra ties so the correct spacing is maintained as displayed in Figure 2.

If additional ties are required, they should not be installed closer than 2 inches to existing preformed holes. Continue reading the instructions below the following figures for instructions on how to drill additional holes.

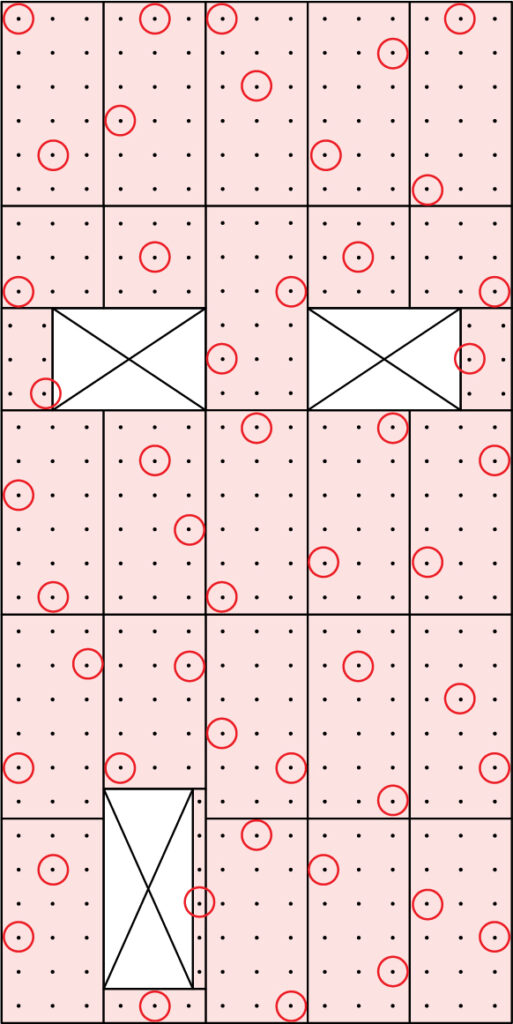

Figure 1 – Highlights common areas near openings and panel edges where tie placements would need to be adjusted.

Figure 2 – Expanded example showing a sheet of rigid insulation that needs tie placement adjustments at the top and right side.

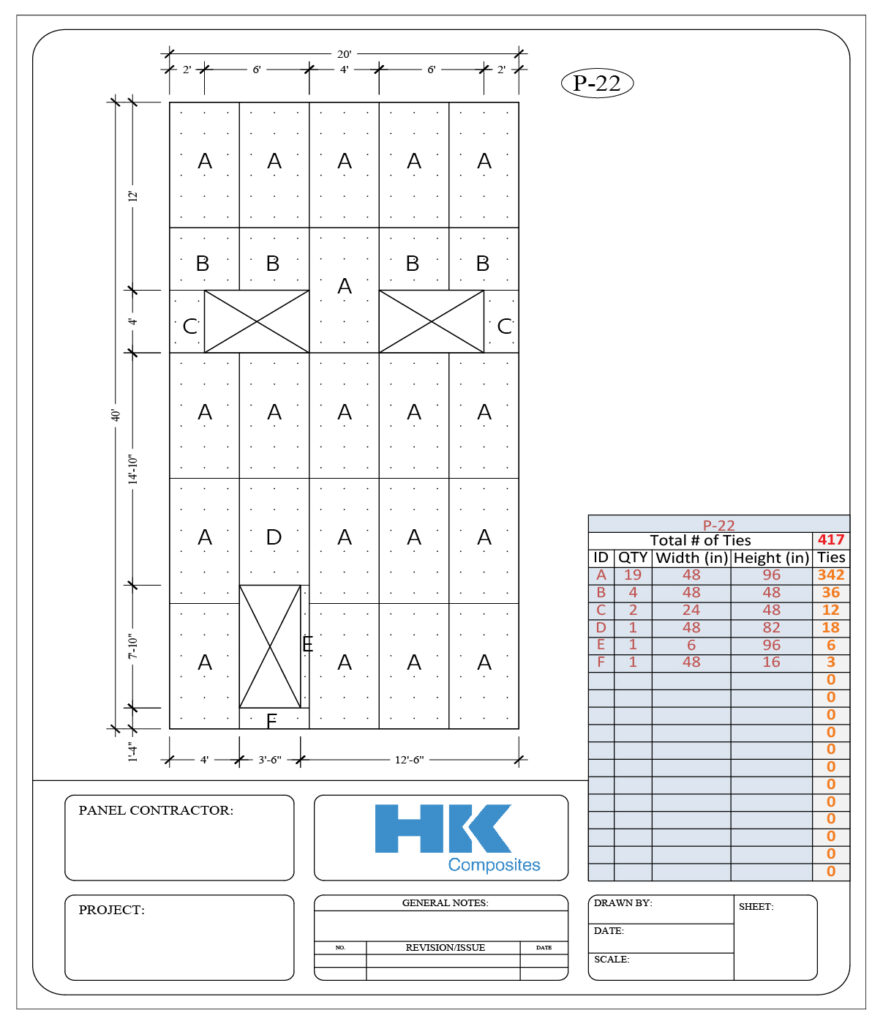

If rigid insulation sheets were custom pre-fabricated off-site and an insulation sheet shop drawing was provided for each panel, all necessary additional holes were already cut in the insulation where necessary for panel edge or opening adjustments. (Figure 3)

However, if custom pre-fabrication was not included for the project and the rigid insulation sheets are not preformed with holes for tie installation, it might be necessary to drill the additional holes where adjusted ties should be installed.

Table 1 indicates the size of drill bit to be used when drilling any holes required to install additional HK Standard (ST) ties.

Drilled holes should be 1/16 inch smaller than the diameter of the tie. (Table 1)

Figure 3 – In this sample shop drawing, the rigid insulation sheets are labeled and marked for placement on the panel as well as marked where the HK Standard (ST) ties should be placed in each sheet.

Table 1 – The complete specifications for each respective HK Standard (ST) tie can be found at https://hkties.com/products/standard-non-composite-products/

The data sheets include each tie diameter which will help in determining the drill bit size if drilling holes is required.

| ST Tie | Drill Bit Size |

|---|---|

| ST50 | 7/16 inch |

| ST75 | 1/2 inch |

| ST100 | 1/2 inch |

5. Check tie consolidation

Performance of the HK Standard (ST) tie system is dependent on having properly consolidated concrete around the pointed anchorage notch of the tie.

In order to check consolidation, temporarily remove one tie per 16 sq ft of the panel (Figure 4). On a standard sheet of 4 ft x 8 ft rigid insulation, this works out to be 2 ties per sheet.

After removing each tie, observe the embedded pointed end of the tie. Wet concrete slurry should be present on the surface of the embedded ends of all observed ties.

If concrete slurry is present, replace the observed tie in the same hole from which it was removed and re-apply vibration surrounding the tie.

If concrete slurry is NOT present, replace the tie and re-apply vibration to that tie. Then re-check the local area by examining all adjacent ties in an expanding perimeter until concrete slurry is present on the embedded ends of each tie tested.

Figure 4 – Sample panel demonstrating potential spots for removing ties to observe concrete slurry.

If slurry is not present on a tie, more testing would be required with adjacent ties.

6. Fill gaps and holes in insulation

Prior to placing the interior concrete wythe, all exposed insulation joints and gaps should be filled with packing dunnage.

Additionally, any unused connector tie holes closer than 4 inches to openings or panel edges should be filled with expanding “foam-in-place” polyurethane foam insulation per manufacturer specifications.

7. Prepare interior wythe

Timing and preparation for the interior concrete wythe is critical.

In order to install interior wythe reinforcing, inserts, and hardware, it is important that the concrete in the exterior wythe reach at least 25 percent of its 28-day strength.

Concrete should have a minimum compressive strength at 28 days as indicated on the project drawings and as required for panel erection, or specified, and tested according to ASTM C39. Minimum strength of panels at time of erection shall be in accordance with the lifting design.

Primary factors affecting concrete strength gain include time and ambient temperature. The following time limits in the table below can be used as guidelines.

| Ambient Temperature Range (Fahrenheit) | Minimum time from fascia casting to installation of reinforcing |

|---|---|

| 70+ degrees | 12 hours |

| 60 – 70 degrees | 24 hours |

| 40 – 60 degrees | 36 hours |

| below 40 degrees | Field-cured cylinder test required |

If you have questions about concrete cure times, please contact our engineering team.

After the exterior wythe has reached at least 25 percent of its 28-day strength, install interior wythe reinforcing, lifting inserts and other hardware.

Workers should avoid disturbing the ties and the insulation layer after the exterior wythe concrete has reached initial set.

8. Perform on-site quality assurance testing

After the exterior wythe has reached the required concrete strength, it is necessary to perform on-site quality assurance tests prior to placing the final concrete layer for the interior wythe.

Visual Testing – These tests confirm all rigid insulation sheets are properly installed and all ties are examined for correct installation. Refer back to the Visual Inspection process in “Step 3 – Install connector ties” above.

Pull Testing – These tests confirm proper concrete consolidation around the HK Standard (ST) Ties. Refer to the HK Composites document titled “ST Tie On-Site Pull Testing”.

9. Place interior wythe

Clean debris before placing concrete.

Place the interior wythe layer of concrete in the forms and screed to specified thickness.

Finish, cure and protect concrete as required.

10. Panel completion

Strip forms and transport/lift the panels into final position.

If present, ensure that vapor retarder will not be damaged during erection.

Additional Questions

We understand what it means to gain client trust, which is why we develop durable, sustainable concrete construction products.

In addition to providing top of the line products, our customer support team and engineering team work hard to ensure our clients are satisfied. If you have any questions about the HK Composites products, please contact us. We’d be happy to assist.

Contact Us

Toll Free:

(800) 430-6316

International: +1 801-763-0907

Frequently Asked Questions

How do HK Ties work?

View the "How it Works" page to see a demonstration video.

Are HK Ties Tested?

Yes. Our patented low-conductivity polymer systems excel in tests for tensile strength, shearing, concrete pull-out, long term alkaline resistance, fire, cyclic fatigue, and many building code certifications. See HK testing reports here.

Do I save money using HK Ties?

Yes. Our simple manufacturing process used to make HK Ties, called thermoforming, reduces our output costs which increases your “bang for your buck”. Not only that, HK Ties reduce the R-value of the wall by less than 1% compared to as much as 75% reduction with steel and/or typical solid concrete section ties. This results in maximum energy savings!

Also, because HK Ties are manufactured using a simple process, they cost less to produce and we can pass along that savings to our users.

Does HK use fiberglass to make Ties?

Being the best means being different; we don’t use fiberglass in our HK Standard Ties. HK Standard Ties are made from an engineered reinforced thermoplastic, enabling our standard ties to be more durable than competitor ties. In contrast, HK Vertical Pour/ Modular Precast Ties and Composite Action Ties are made from a fiberglass reinforced thermoplastic.

Regardless of the engineered make-up, all HK Ties are designed to resist impact and shock loads during precast panel transportation and erection. The resin retains its strength at high temperature and provides maximum long-term chemical resistance.

Construction jobs come in many different shapes and sizes. Different jobs require different ties. Our HK Tie experts are here to help you find the best tie for your project. Contact us today!

Is plastic as strong as fiberglass?

Fiberglass is plastic—reinforced with glass fiber. Strength-wise, it is true that some types of fiberglass have a higher material tensile strength than HK Tie resins. However, high material tensile strength is only one factor responsible for the tensile capacity of a tie. The minimum cross-sectional area and manufacturing processes together with inherent material properties ultimately determine tie strength. The actual delivered tensile and shear strengths of HK Ties are many times higher than required.

The plastic used for the HK Standard Ties is a high-impact, high-temperature, chemical resistant engineered thermoplastic. The plastic used for the HK VP (Vertical Pour) and Modular Precast Ties is glass fiber reinforced.

Every job is another dragon to slay. We will help you get the job done cost-effectively, safely and as quickly as possible. Contact us today!

Can my project receive LEED points for using the HK Building system?

Yes. With the HK building system, you can go green and save green. HK Green Building Insulation Systems are designed to meet green building standards for better thermal protection and energy performance from longer-lasting, environmentally benign building materials.

The system is created using extruded polystyrene foam (XPS) insulation in-between two concrete wythes. Highly durable HK Ties, inserted into the XPS, have been proven to reduce the insulation R-value by less than 1% Compare that to as much as 75% reduction with steel and/or typical solid concrete sections! This small change can make a big difference! Start saving and contact us today.

Does HK offer a turnkey solution?

Yes. Our turnkey foam fabrication solution is one of many reasons why we are the concrete sandwich construction industry leader. We specialize in and have extensive experience with foam fabrication processes.

When the foam is fabricated, boards are pre-cut to fit architectural drawings. We make it easy for you as we provide specific foam layout drawings and pre-drill the XPS energy-efficient insulation board to accommodate HK Tie insertion. HK insulation foam boards come to the job site, placement ready. Bye, bye head scratching and complicated puzzles, hello revenue.