| Location |

| Bruceton Mills, West Virginia |

| Completed |

| January, 2004 |

| Total Size |

| 650,000 sq ft |

| Engineer |

| KZF Architectural Firm |

| HK Products |

| Standard System |

| Project Website |

| Visit site |

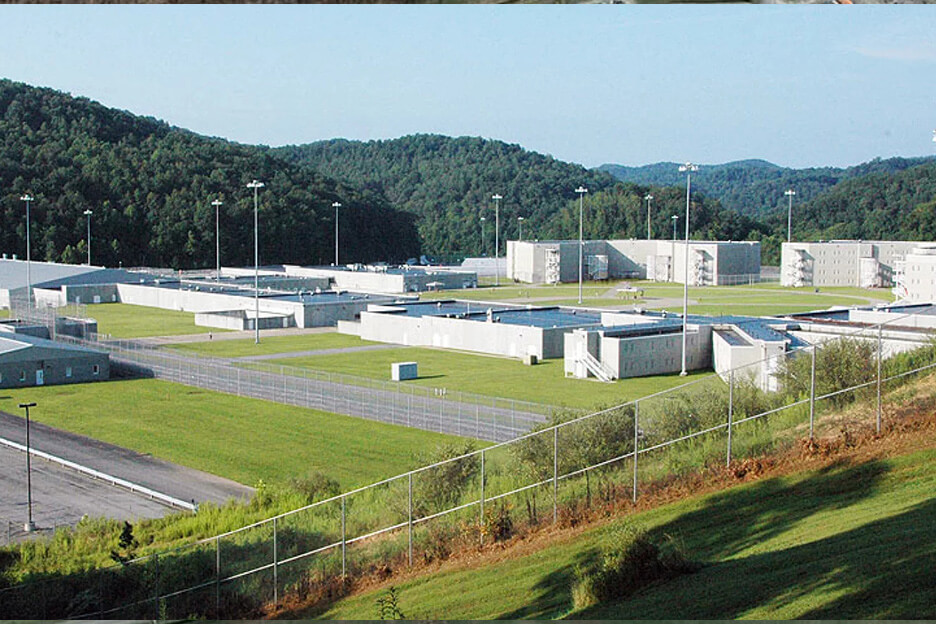

The United States Penitentiary, Hazelton (USP Hazelton) is a high-security United States federal prison for male inmates in West Virginia. It is operated by the Federal Bureau of Prisons, a division of the United States Department of Justice. The facility has a satellite prison camp for minimum-security male offenders, as well as a Secure Female Facility that houses female inmates

USP Hazelton was built due to an increasing need for modern facilities to house the growing number of federal inmates. The high security facility and the satellite minimum security prison camp cost $129 million to build and takes up 996 acres, and were designed by KZF Architectural Firm.

The high-security facility, completed in 2004, contains six two-story buildings with 768 general housing cells and 120 “special housing cells” where especially dangerous prisoners are housed. In addition, there are several one- and two-story buildings which house various prison programs, as well as a factory where prisoners work. It is surrounded by a triple security fence with a taut wire system, and six guard towers around the perimeter.

John Malonoski, project manager for the Hazelton job, said “The precasting process gives the project a major schedule advantage because we can be casting and outfitting cells modules while other work at the site is still going on. The system also has benefits in production quality.”

“It’s a modular system,” explains Malonoski. “The process is repetitive. With the exception of perhaps moving electrical boxes or other components within the modules, you are basically being repetitive every day. The molds are set up to be repetitive. The people who are doing the work get good at it. It becomes a routine. You get the same quality on a day-in-and-day-out basis.” Malonoski says the construction process is like building a box all at once, with four walls, a floor and a roof. The first level sits on a slab-on-grade that;s in place, and the second level sits on top of the first level. Generally, housing modules are two levels high, as was the case at Hazelton. Some jobs are higher. “We cast our cell modules in steel forms,” explains Malonoski. “We pour either two or four cells at a time for a module. Two cells make up a double-cell module, or four make up a quad-cell module.

“A steel-reinforcing cage for the module is prefabricated and dropped into the mold, along with the insulation for the exterior wall. It is easier to secure the insulation to the cage and drop it in that way than to add it once the reinforcing cage is in place.

“At Hazelton, there is a 10-inch thickness overall on the exterior wall,” he continues. “That includes a 5-inch interior concrete wythe, 2 inches of foam insulation and a 3-inch exterior wythe. The HK Composites patented connector ties are used to link the wythes together.”

The gray walls at Hazelton may look cold and forbidding but they have a core of pink foam insulation that locks up energy savings every day.